FLEXIBLE. EASY TO HANDLE SYSTEM.

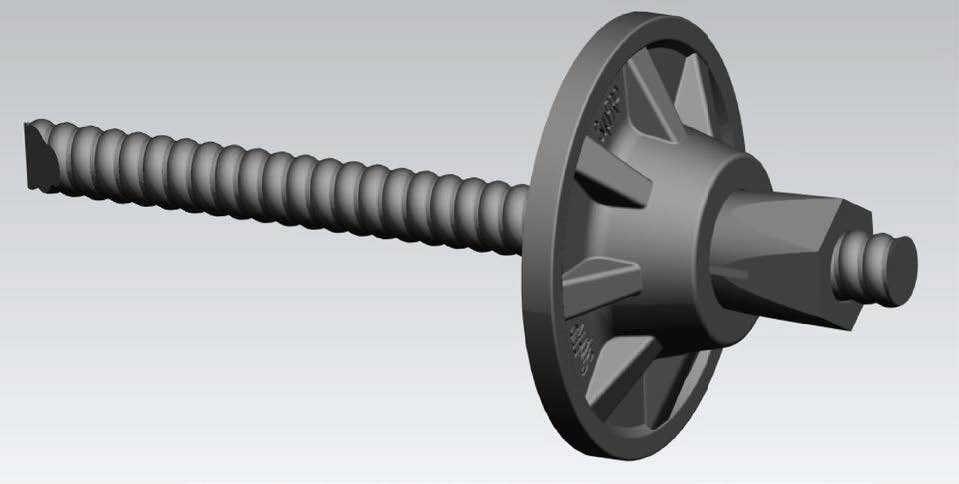

Glassfibre resin polymer (GFRP) bolting system is a comprehensive rock bolting system with various components that include a plastic nut, GFRP nut, steel nut, plastic plate, GFRP plate, couplings, adapter and injection connection. Available as solid and hollow bolts

The bolt has a high ultimate load and due to its profile, offers a maximum bond strength with all grouting materials. The bolt has a continuous thread and can be trimmed if required.

Solid bolts can be installed with cement grout or Lokset® resin capsules, while the installation of the hollow rods can be carried out with cement grouts or injection resins.

Continuously threaded, high strength rock bolting solution. Developed for strata support in mining and tunnelling, it has proven to be a versatile product for many applications. The GFRP system allows the bolts to be cut to length as required on location, as well as protecting equipment and machinery of they are required to be mined through. Due to it's high corrosion resistance, it is perfectly suited for long term and temporary ground support.

- HIGH TENSILE STRENGTH

- CUTTABLE

- HIGH CORROSION RESISTANCE

- High ultimate load with a maximum bond strength between anchoring materials

- High corrosion resistance and suitable for permanent support

- Cuttable protecting machinery and equipment, preventing damage when drifting and enlarging tunnels

- Continuous thread allows easy trimming of bolts if required

- Low weight facilitating easy handling, minimises transport requirements

- High flexibility suitable for applications without couplings in confined locations

- Available in hollow and solid versions

- Anti-static options available

| Mechanical Property (Typical) | S20/200 Rock Bolt | S22/250 Rock Bolt | S25/350 Rock Bolt |

|---|---|---|---|

| Outer Diameter (mm) | 20 | 22 | 25 |

| Tensile Stress Area (mm2) | 200 | 250 | 350 |

| Ultimate Load (kN) | 200 | 250 | 350 |

| Breaking Load Thread - Steel Nut (kN) | 100 | 120 | 180 |

| Breaking Load Thread - GFRP Nut (kN) | 60 | 70 | 70 |

| Breaking Load Thread - GFRP Conical Nut (kN) | 80 | 100 | 180 |

| Torsion Resistance (Nm) | 70 | 80 | 120 |

| Tensile Modulus (GPa) | 50 | 50 | 50 |

| Strain at Failure (%) | 2 | 2 | 2 |

| Weight (g/m) | 560 | 690 | 900 |