Ventilation systems to ensure clean air in underground mines.

To help ensure clean air in underground mines we offer a range of solutions that include automatic airflow regulators, secondary air control and plastic regulator drop boards.

In 2005 we developed a revolutionary new automatic airflow regulator, Blastflow®, for Hard Rock mines that can be retrofitted to existing regulator sites. Secondary fans can be combined with automated Blastflow regulators to allow the mine to control where and when air is placed. Ventilation on Demand (VOD) allows an underground mine's ventilation circuit to be electronically controlled delivering airflow efficiency, reduced electricity and rapid access to production areas.

To control air flow at stope accesses and draw points, ore passes and the general direction of ventilation throughout mine areas we offer ventilation blinds (QBC). Designed to suit specific size openings and can be relocated for re-use.

To control air quantities in an underground mine circuit we offer environmentally friendly, recycled plastic drop-boards.

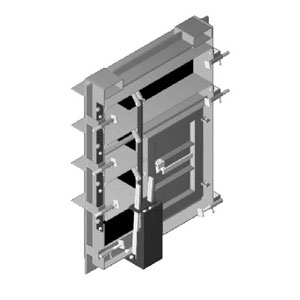

Blastflow Louvre Regulators

Provide enhanced control of airflow in primary ventilation circuits which are subject to air overpressures from stope firings. Blastflow maximises the time available to underground operators by allowing them to work in a controlled ventilation environment right up to the time of the blast. Once adjusted, airflow is regulated immediately before and after the blast. Blastflow can be converted to allow remote control of the modules through the use of electric actuators and the mines SCADA system.

Advantages:

- ”Set and forget solution” - simple hand wheel adjustment that establishes airflow settings before and after stope firings

- Reduced safety risk exposure as operators are not required to remove hardwood drop boards and other ventilation controls before firings

- Minimise manual handling by simply lifting modules into place using an ITC and locking pins for fixing inside steel regulator frames

- Modules can be interchanged at other regulator sites, allowing for increased design flexibility

- No requirement to disassemble before blasting

- Blastflow modules can be fitted with man-doors, and the frame centre struts can be removed on double and triple 7 blade module regulators to enable light vehicle access

- Workers aren’t exposed to return air dust and removing timber boards

Ventilation Blinds

Minova’s QBC blind is an easy to install ventilation device that allows for stopping of airflow to or from the area of a mine that may require access at a later stage. Designed for a wide range of operating pressures to suite any opening size up to 5.6 metres in width. QBC Blinds have been developed for a wide range of applications in underground metal mines, coal mines and rail tunnels.

Advantages:

- Easily installed using existing mine services

- Can be opened and closed with one person in a few seconds to allow vehicle and truck access

- Can be tailored to suit specific size and ventilation requirements

- Durable and high tensile cloth eliminates wear and impact damage

- Flexible support ribs eliminate damage due to excessive ventilation pressure

- Easily relocated for use where required

- Approved cloth material for use in coal mines

- CUSTOM MADE

- ONE PERSON OPERATION

- SIMPLE TO USE, EASY TO INSTALL

- Custom Made

- One person operation

- Simple to use, easy to install